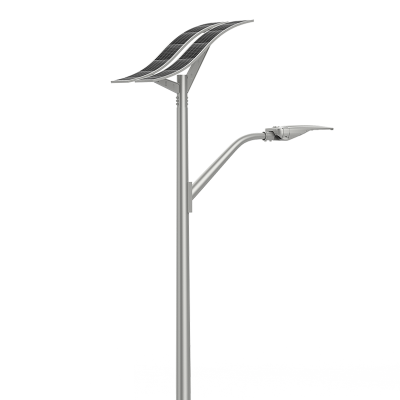

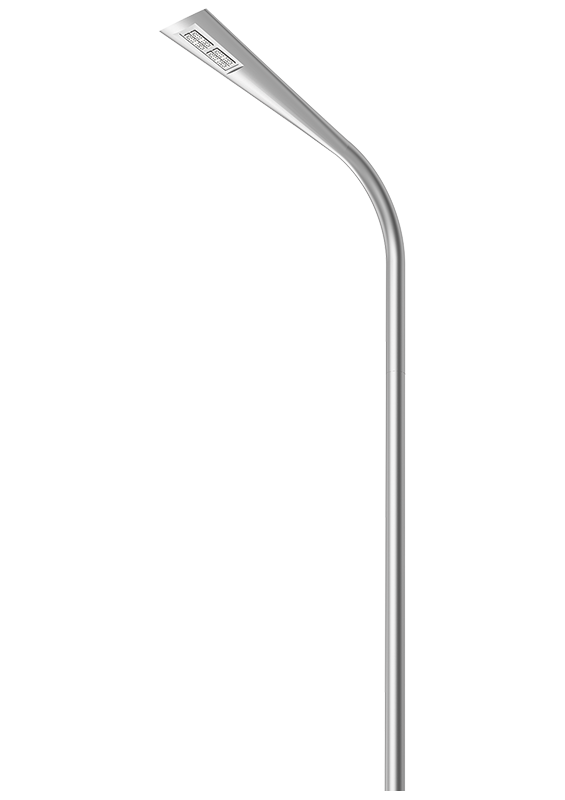

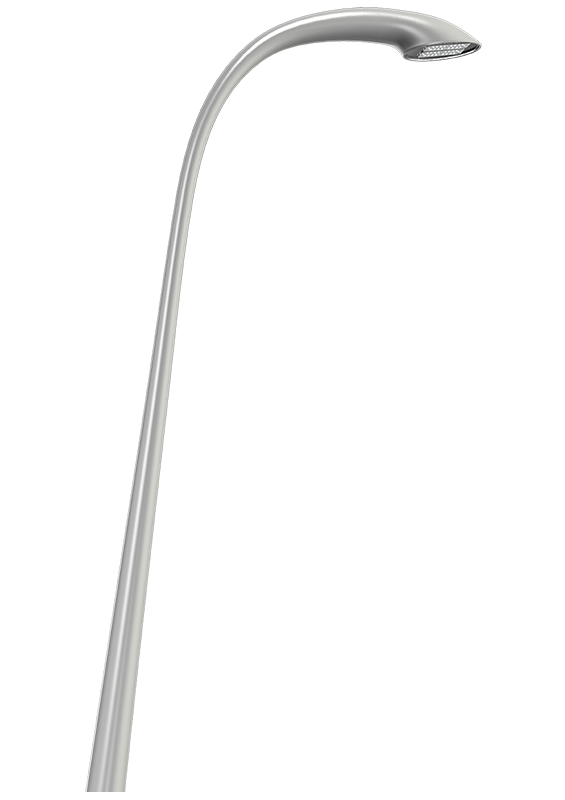

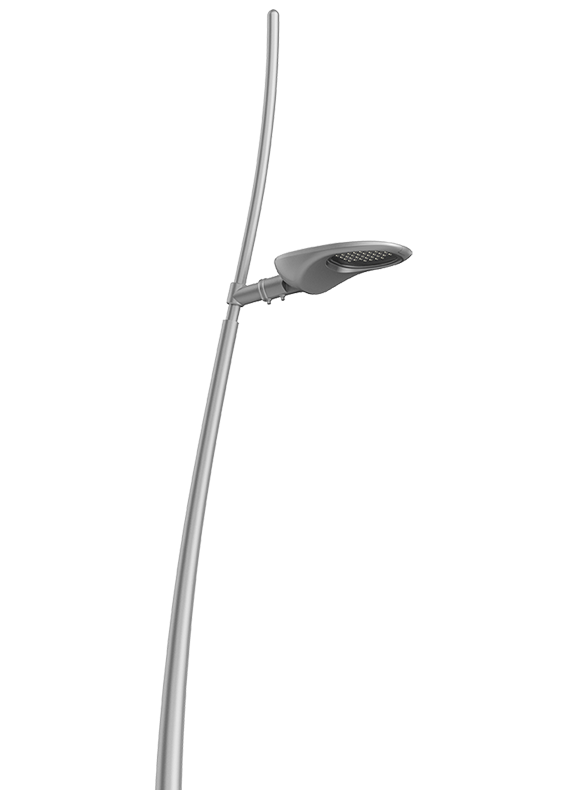

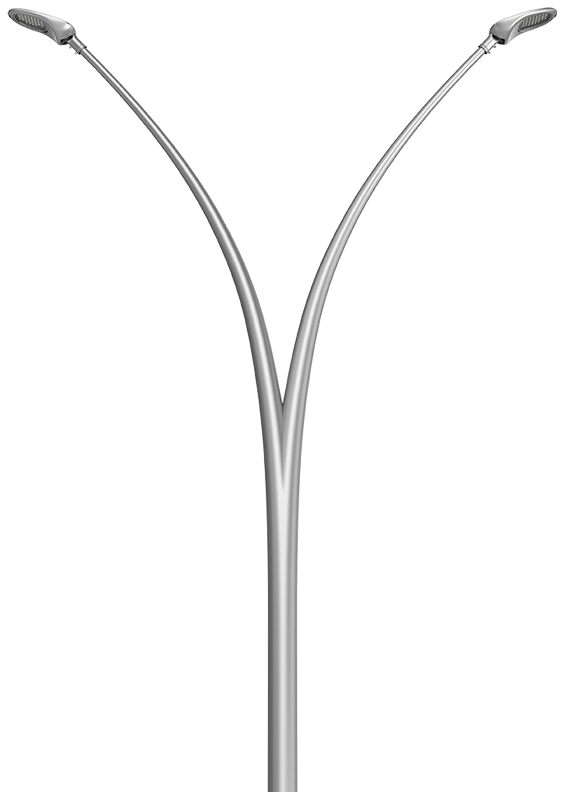

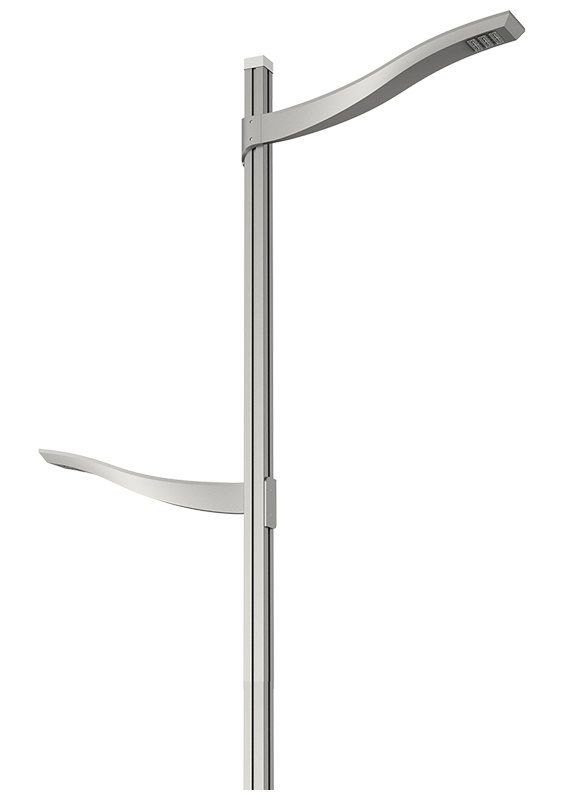

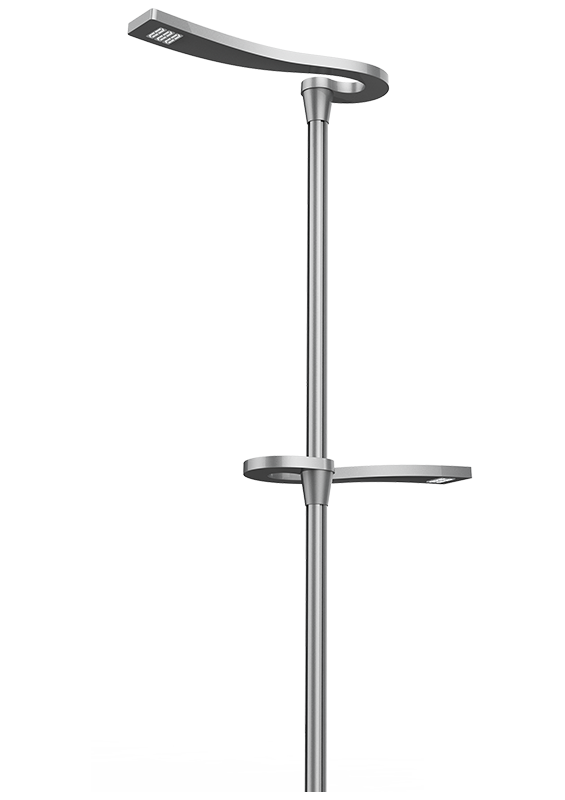

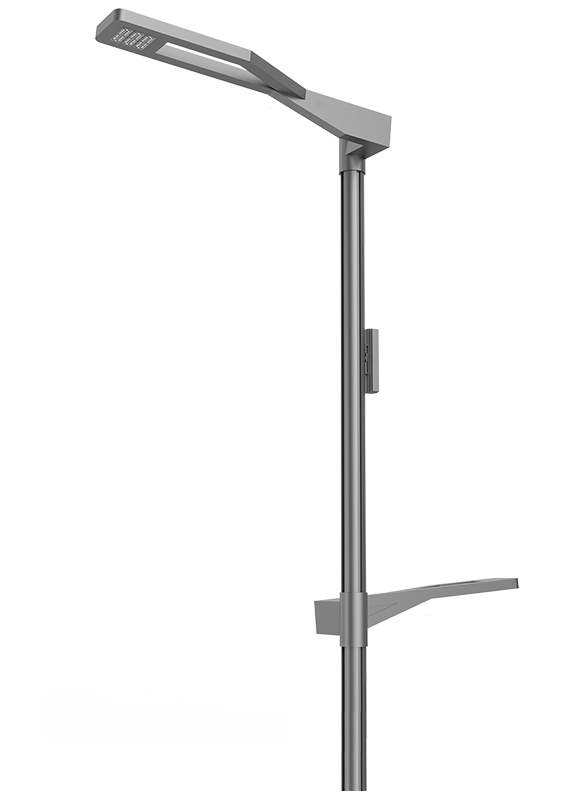

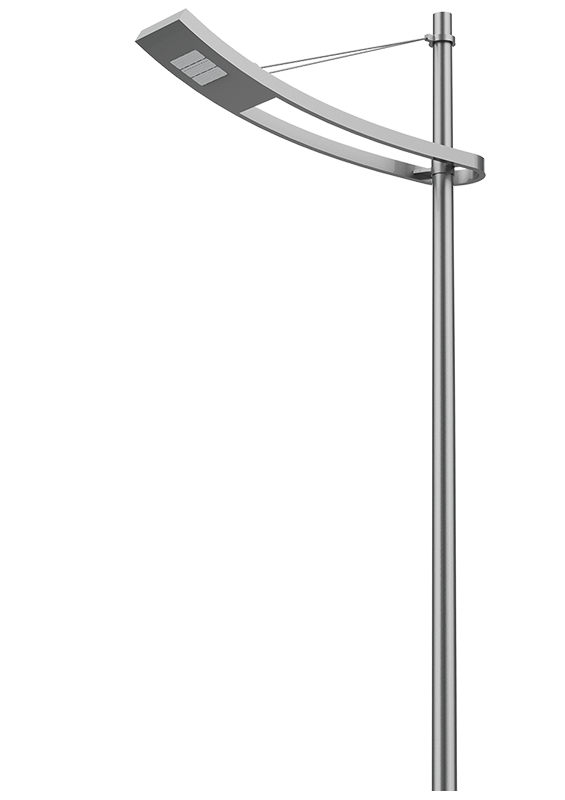

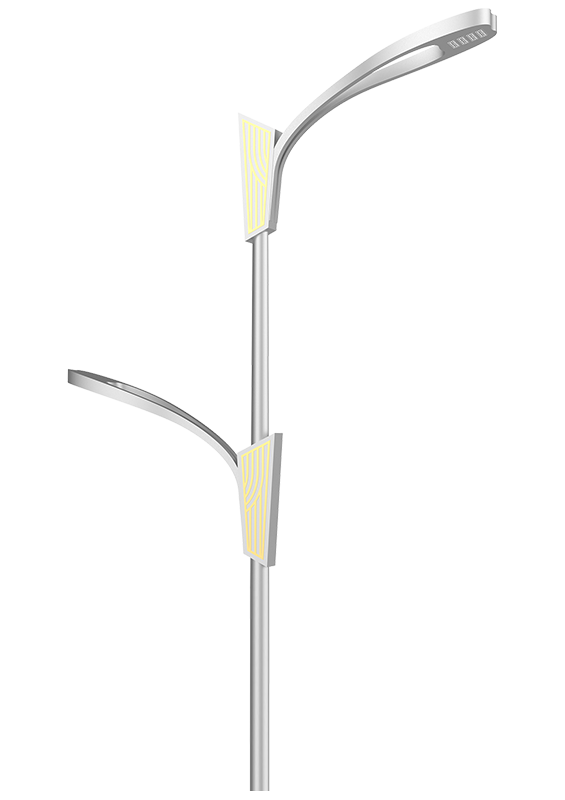

Aluminum Street Light Pole

- Made of strong 6063 T6 aluminum alloy.

- Seamless, weld-free from one-piece forming.

- Surface finished with anodizing or powder coating.

Spinning 6063 T6 Aluminum Light Pole

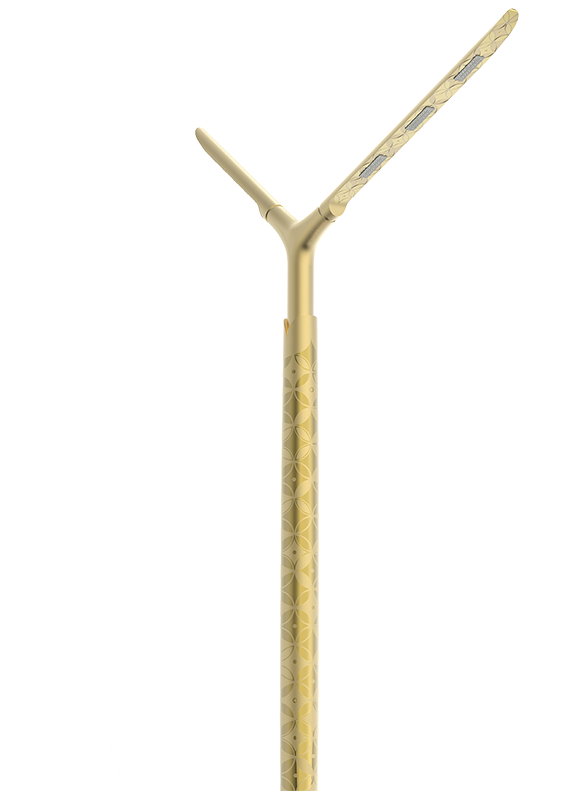

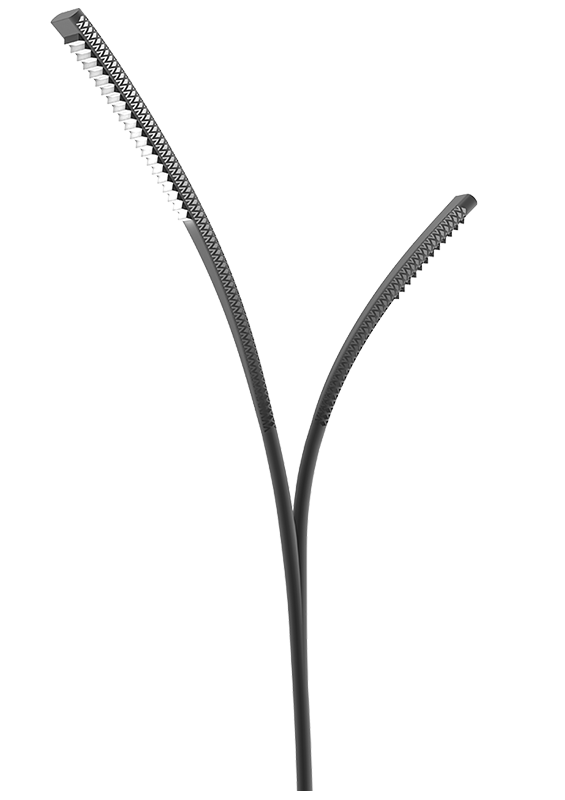

A 6063 T6 aluminum light pole is a type of streetlight or outdoor lighting pole made from 6063 aluminum alloy in the T6 temper condition. Here’s a breakdown of the key aspects: 1. Material: 6063 Aluminum Allo 6063Aluminum: This is a commonly used aluminum alloy known for its excellent extrudability, making it ideal for forming into shapes like light poles. It has good corrosion resistance, moderate strength, and a smooth surface finish, which is often desirable for aesthetic purposes. T6 Temper: The “T6” designation refers to the heat treatment process the aluminum undergoes. T6 temper involves solution heat treatment followed by artificial aging, which increases the strength and hardness of the material. This makes the light pole more durable and capable of withstanding environmental stresses. 2. Applications Street Lighting: Commonly used for streetlights, parking lot lights, and other outdoor lighting applications. Decorative Lighting: Often chosen for decorative light poles in urban areas, parks, and pedestrian walkways due to its sleek appearance. High Mast Lighting: Suitable for high mast lighting systems used in stadiums, airports, and large outdoor areas.

3. AdvantagesLightweight: Aluminum is much lighter than steel, making transportation and installation easier. Corrosion Resistance: Naturally resistant to rust and corrosion, making it ideal for outdoor use in various climates. Aesthetic Appeal: Can be easily anodized or painted for a polished, attractive finish. Durability: The T6 temper provides enhanced strength, ensuring the pole can withstand wind, weather, and other environmental factors. 4. Design Considerations Height and Diameter: Light poles can vary in height and diameter depending on the application (e.g., 20-40 feet for streetlights, up to 100 feet or more for high mast lighting). Wall Thickness: The thickness of the aluminum walls affects the pole’s strength and weight. Base Design: Typically includes a flanged base for anchoring to a concrete foundation.

5. Standards and Certifications ASTM B221: Standard specification for aluminum extruded bars, rods, wire, profiles, and tubes. AASHTO: American Association of State Highway and Transportation Officials standards for light poles used in public roadways. Wind Load Ratings: Must meet specific wind load requirements based on the installation location. 6. Maintenance Requires minimal maintenance due to its corrosion resistance. Periodic inspections for structural integrity and cleaning may be necessary to maintain appearance.

Yaolong is a specialized manufacturer of high-performance aluminum light poles, offering three primary models: Round Tapered Aluminum (RTA), Round Straight Aluminum (RSA), and Square Straight Aluminum (SSA). Each pole is engineered for exceptional durability, aesthetics, and longevity.

Our core manufacturing advantage lies in the advanced rotary spinning technique. This process allows the entire pole body to be formed seamlessly from a single piece of aluminum, eliminating welds and creating a uniform, structurally superior profile. Following forming, the poles undergo precise heat treatment to achieve a T6 temper, a grade that grants them strength comparable to structural steel while maintaining the lightweight benefits of aluminum.

To ensure maximum resilience against harsh environmental conditions, Yaolong poles receive a robust protective finish. We employ either high-quality anodization or premium powder coating. These surface treatments provide an exceptional barrier against corrosion, UV radiation, and weathering, significantly extending the service life and maintaining a pristine appearance for years.

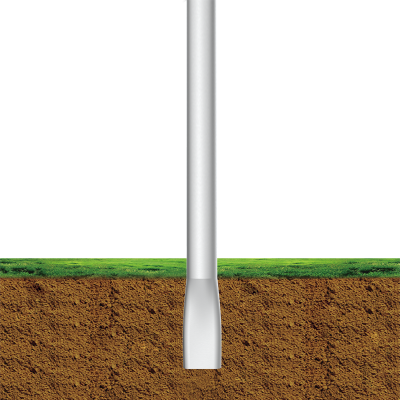

We offer flexible installation solutions to meet diverse project requirements:

Direct Burial: Poles can be directly embedded into the ground for a streamlined, foundation-free installation.

Anchor Base: Poles are secured to a pre-installed concrete foundation using anchor bolts, providing a strong and adjustable mounting option.

By combining seamless spinning construction, T6-grade strength, advanced anti-corrosion finishes, and versatile installation methods, Yaolong delivers aluminum lighting solutions that are not only reliable and strong but also offer a sleek, modern aesthetic for urban landscapes, roadways, and architectural projects.