Aluminum Direct Burial Light Pole

15-min Fast Install & Save Time & Reduce Costs

- Model:

- Materials:

- Height:

- Min. Diameter:

- Max. Diameter:

- Wall Thickness:

- Wind Resistant:

- YLDG-DB

- 6061 6063 T6 Aluminum Alloy

- 3-12 Meters

- 60 mm

- 255 mm

- 2.5-6.0 mm

- 180KM/H

- 10-40 Feet

- 2.36 Inches

- 10 Inches

- 0.1-0.25 Inches

Aluminum Direct Burial Light Pole Specification

The Aluminum Direct Burial Light Pole shaft is crafted from precision-spun, seamless 6063 T6 aluminum alloy tubing.

| MODEL | HEIGHT | TOP OD | BASE OD | ARM | THICK | DOOR HEIGHT | DOOR SIZE |

|---|---|---|---|---|---|---|---|

| YLDG-DB1 | 5000 | 80 | 152 | 1500 | 4.0 | 500 | 80x250 |

| YLDG-DB2 | 6000 | 80 | 152 | 1500 | 4.0 | 500 | 80x250 |

| YLDG-DB3 | 7000 | 80 | 166 | 1500 | 4.0 | 500 | 80x250 |

| YLDG-DB4 | 8000 | 80 | 180 | 1500 | 4.0 | 500 | 100x300 |

| YLDG-DB5 | 9000 | 80 | 180 | 1500 | 4.0 | 500 | 100x300 |

| YLDG-DB6 | 10000 | 80 | 200 | 1500 | 4.0 | 500 | 100x300 |

Surface Treatments

The standard finish for the pole assembly and components is satin brushed, natural anodize, duranodic or polyester powder applied coating in accordance with Landmark’s Specifications. Additional finish options available upon request

Aluminum Direct Burial Light Pole

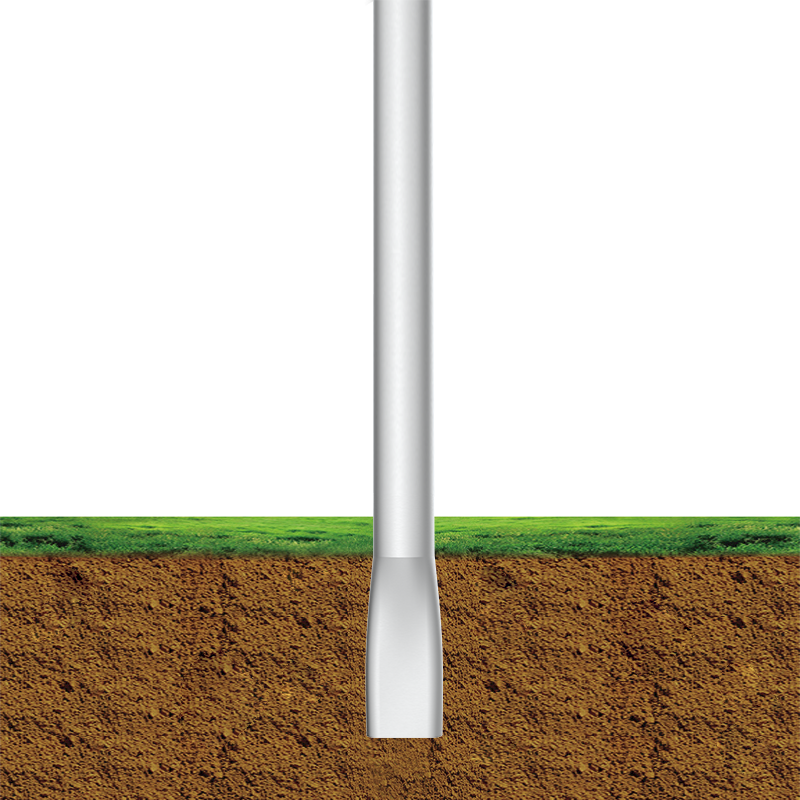

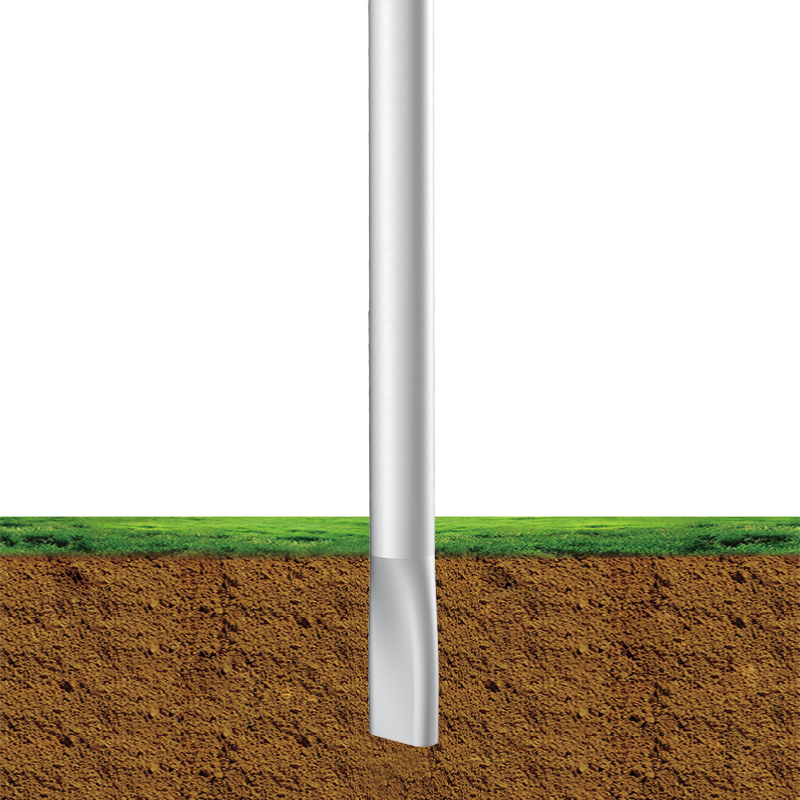

An direct burial aluminum light pole is a common and reliable technique, but it must be executed with one critical safeguard: isolating the aluminum from the soil and any dissimilar metals.

The absolute standard practice is to use a factory-coated pole. The portion of the pole that will be buried (typically from several inches above grade to several feet below the required depth) is abrasive-blasted and coated with a thick, tough, non-conductive material like polyurea or coal tar epoxy. This coating acts as a dielectric barrier. It prevents galvanic corrosion, which occurs when the aluminum is in direct contact with moist soil and dissimilar metals like the steel anchor bolts or rebar in the concrete foundation. You should specify this when ordering; it’s often called a “Dura-Buried,” “poly-coated,” or “protected base” pole.

During installation, you follow the manufacturer’s engineered foundation drawing. The pole is set in the hole, made perfectly plumb, and then backfilled. The best backfill material is clean, crushed stone, as it provides excellent drainage and is non-corrosive. You must use Schedule 80 PVC for the underground electrical conduit. All grounding must be done correctly, and the electrical connections should have GFCI protection.

The simple rule is this: Never put bare aluminum directly into the ground in contact with concrete and steel. The cost of a properly coated pole is minor compared to the cost of replacing a failed one a few years later. Always get and follow the manufacturer’s specific foundation drawing for your pole’s height and local wind conditions.