Advanced Equipments

Yaolong’s advanced equipment ensures high precision, durability, and efficiency in producing aluminum light poles, making them suitable for street lighting, highways, stadiums, and urban landscapes.

CNC Spinning Equipment

- Used for shaping aluminum poles into apered, conical, or cylindrical forms with high precision. - Benefits: Ensures smooth surfaces, consistent wall thickness, and complex geometries.

15-meter Automatic Anodizing Pool

Applies a protective anodized oxide layer to aluminum poles for enhanced corrosion & UV resistance. Benefits: Improves durability, allows for color customization (silver, black, bronze, etc.), and extends lifespan.

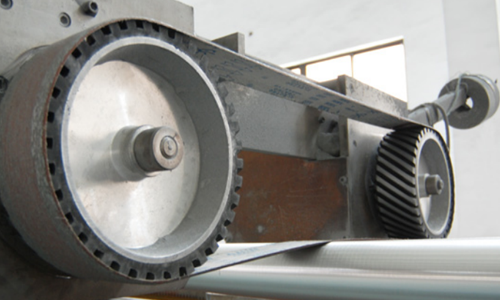

Belt Grinding Machine

- Polishes and smoothens aluminum surfaces, removing imperfections before finishing. - Benefits: Ensures a flawless surface for anodizing/painting and improves aesthetic quality.

Automatic Cutting Machine

Precisely cuts aluminum poles to required lengths with laser-guided accuracy. Benefits: Reduces material waste, ensures consistency, and speeds up production.

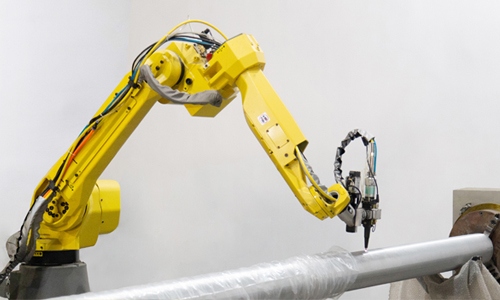

Automatic Welding Robot

- Performs high-precision TIG or MIG welding for seamless joints and structural integrity. - Benefits: Enhances weld quality, reduces human error, and increases production efficiency.

Laser Cutting Machine

- Used for cutting flanges, brackets, and mounting holes with extreme accuracy. - Benefits: Allows for intricate designs and clean edges without burrs.

T6 Heat Treatment Oven

- Strengthens 6063 aluminum by solution heat treatment & quenching, followed by artificial aging. - Benefits: Increases tensile strength & hardness while maintaining ductility.

Horizontal Aging Oven

- Completes the T6 tempering process by artificially aging aluminum for optimal mechanical properties. - Benefits: Ensures uniform hardness and stability across all lamp poles.